疫情期間,全港每日棄置數以百萬計外科口罩,為堆填區帶來沉重負擔,並有機會危害海洋生態。為解決此痛點,香港初創企業ÖKOSIX(綠適有限公司)推出全球首款醫療級「全走塑」口罩,可在6個月內迅速降解成二氧化碳、水及其他無害物質。

與NAMI合作研發環保物料

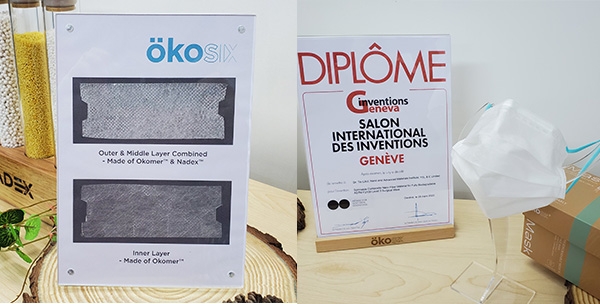

ÖKOSIX團隊與NAMI(香港納米及先進材料研發院)合作,運用「靜電紡絲」及「優化纖維」技術,把植物纖維和天然物料造成NADEXTM納米過濾層和OkomerTM物料,物料更榮獲日內瓦國際發明展金獎。ÖKOSIX除了製造口罩外,還計劃研發及製造可降解空氣濾網、尿片及衛生巾等消耗性產品,推廣環保「走塑」生活。

ÖKOSIX創辦人于紹龍(Eddie)數年前於香港貿發局主辦的「國際環保博覽」上認識了NAMI的科學家,為雙方日後合作埋下伏線。

有感傳統口罩不環保,他遂於前年把口罩廠賣盤,把資金全數投放在研發可降解口罩。為了縮短研發時間和資源,于紹龍選擇與NAMI合作,在他們現有的技術基礎上再進行研究,把科研成果商品化。

獲日內瓦國際發明展金獎

于紹龍說,ÖKOSIX的品牌理念是「取於自然、歸於自然」,從美國、中國內地、新加坡等地搜羅各種原材料,並反覆測試以達到最佳效果。「簡單來說,傳統口罩以塑料加熱熔噴拉絲製成;我們則以植物纖維素、多醣體及多種天然物料,運用『靜電紡絲』科技製成NADEXTM 納米過濾層和以『優化纖維』技術製成OkomerTM 物料,再加工製造成為可完全生物降解、兼具頂級防護力的ASTM F2100三級外科口罩,有效阻隔細菌、病毒及飛沫。」

他指出,整個ÖKOSIX口罩包括鼻樑條及耳繩,都可以在6個月內完全降解為二氣化碳、水及其他有機物質。「產品已通過國際認可的厭氧可降解測試ASTM D5511,以及含氧可降解和可堆肥物料認證ASTM D6400;EN13432中的崩解、有毒物質、可降解及生態毒性測試,是全球第一個可降解可堆肥認證的醫療級口罩,保證ÖKOSIX口罩能夠在6個月內完全降解,而且不會產生微塑膠、重金屬或其他對環境生態有害的物質。我們剛於3月取得日內瓦國際發明展金獎,並準備在香港、中國內地、美國及歐洲多國申請專利。」該技術亦得到創新科技署的支持。

線上線下銷售新產品

ÖKOSIX口罩於本季開售,每個零售價約為4港元,與一般塑膠製口罩相若。除了設立自營網站外,于紹龍亦計劃透過其他網購平台銷售產品,並積極考慮開設零售店,兼售「綠適口罩」以及其他可持續產品。

隨着疫情漸穩定,不少國家已解除戴口罩規定,但于紹龍毋懼業務受影響。「除了消費者外,醫療機構及大企業以至其他口罩生產商,都是我們的目標客戶。ESG議題日漸受關注,大企業都會樂於採用環保產品,我們已經和不少潛在合作夥伴洽商中。此外,純天然可降解物料用途非常廣泛,無論是冷氣機/空氣濾網、尿片和衞生巾都可應用,以取代目前的塑膠材料,這是很大的市場。」因此,ÖKOSIX已經吸引到投資者留意並注資。

與環保署合作研究

展望未來,于紹龍希望與環保署合作,從堆填區取得土壤,以研究在香港潮熱環境下,哪種溫度、濕度、天然細菌最有利產品加速降解。「在模擬堆填區無氧降解測試中,產品在90日內已可降解超過九成。」

他亦有意通過貿發局展覽會及服務,進一步推廣業務,接觸海外及內地買家,開拓國際市場。

原文: 創業快綫| 商貿全接觸