Limitations of Current Recycling Technology

Studies show that our planet is increasingly choked by plastic pollution, with production far exceeding safe limits. One of our collective goals is to create a true recycling economy, where existing plastic waste can be re-used in high-quality applications to reduce our environmental footprint.

Everyone likes recycling.

But why is only 10% of plastic waste recycled on a global scale?

This is because every time plastic is remelted and reprocessed, it loses 20-40% of key properties like strength, flexibility, and temperature resistance. This means while the plastic is technically still recyclable, its declining functionality and value per cycle mean it can’t be reused for the same product.

Ecotec technology enhances the recycling process by restoring properties and thereby boosting the value of recycled plastic materials, enabling them to be repurposed for building construction and packaging and consumer goods, and more.

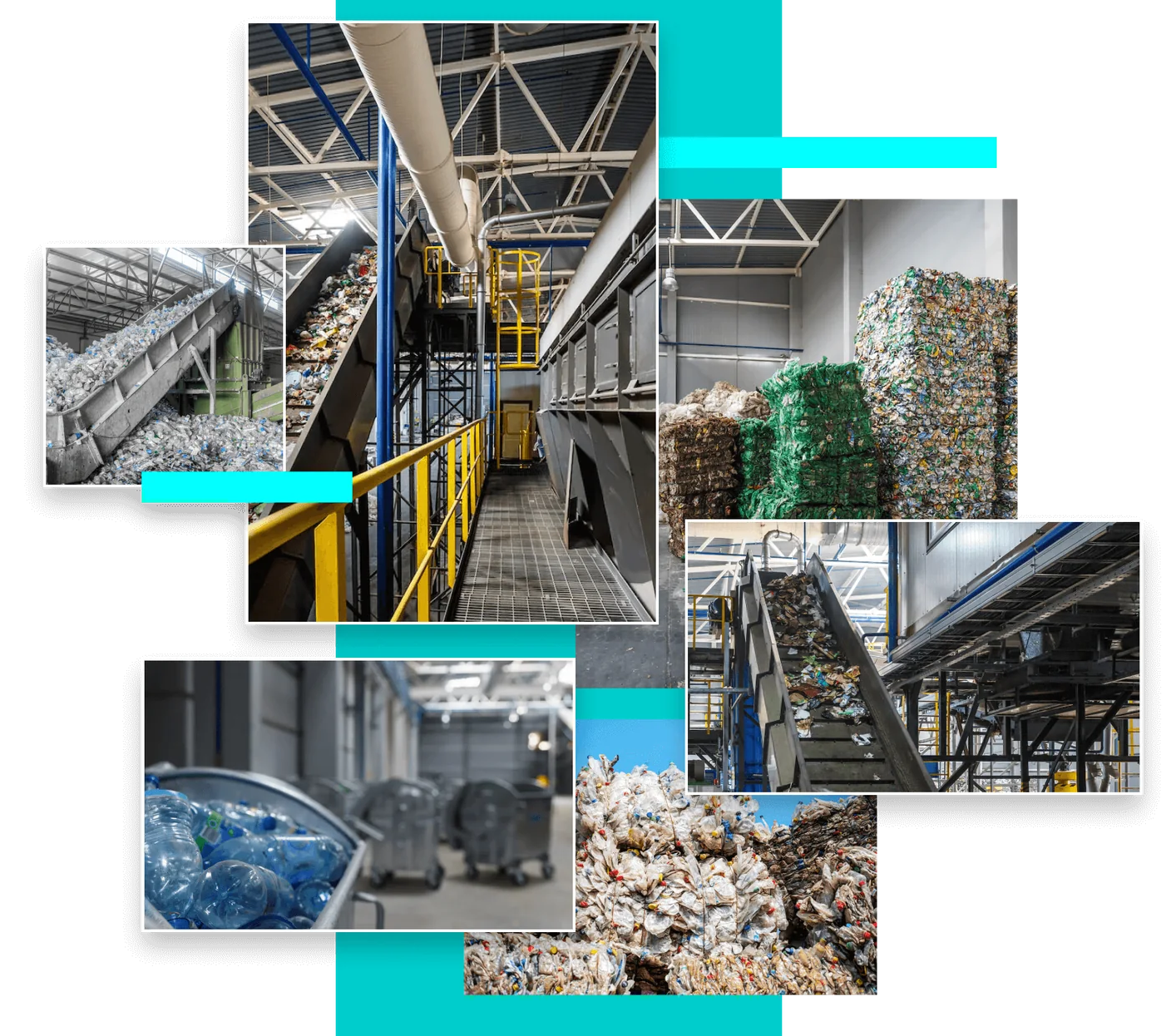

Once the recycled plastics arrive at our factory, they will be treated with the following processes:

- Sorting

- Characterisation

- Washing

- Shredding

- Identification and Separation of plastics

- Extruding and Compounding